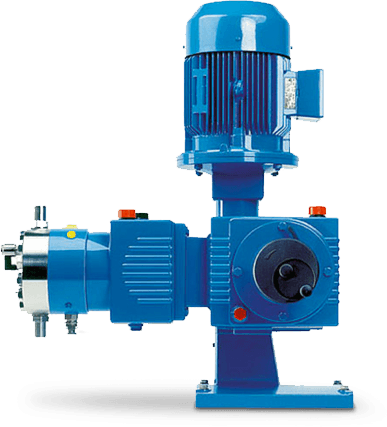

LEWA PUMP

MODEL ECOFLOW

The all-around talent for virtually all industries. Its sophisticated modular system makes the ecoflow diaphragm metering pump the correct industrial pump for almost all applications.

Whether toxic, abrasive or sensitive liquids – the ecoflow diaphragm metering pump is the first choice for almost all fluids.

Our experts design drive units and pump heads for you individually. The ecoflow series implements a flow rate of up to 19 m³/h per pump head and a discharge pressure of up to 1200 bar.

No matter if offshore in rough seas or in production in pharmaceutical cleanrooms – the ecoflow diaphragm metering pump has established itself worldwide in a range of different industries as a reliable and economical metering pump.

It features an exact metering rate and enormous durability in extreme operating conditions. Low life cycle costs and high energy efficiency complete the profile of a true all-around talent.

Thanks to the tried-and-tested modular system, ecoflow diaphragm metering pumps can be configured with various pump heads and drives for almost all applications. Here, we set technological and qualitative standards: Each ecoflow diaphragm metering pump is equipped with the patented DPS diaphragm protection system and produced in Germany.

Good reasons for a LEWA ecoflow®

The LEWA ecoflow is a hydraulically actuated diaphragm metering pump that provides numerous advantages over comparable pumps.

Unique suction capacity

The LEWA ecoflow diaphragm metering pump differs from other pumps due to its unique suction capacity. With an absolute suction pressure of up to 0.1 bar abs., it not only provides a wide array of safe installation options. The operating costs for the entire system can also be lower than with other pumps.

Absolutely safe startup

Starting up the metering pump is safe and easy: When the pump is not operating, a spring pulls the diaphragm into a safe position at all times. This allows us to guarantee maximum safety when starting up your system and a long service life of the diaphragm.

Low maintenance costs and a long service life

The ecoflow series features a long service life for all components and particularly low maintenance and operating costs. If the regular maintenance intervals are maintained, our diaphragm pumps can operate for 40 years or more in your production process.

API 675 standard

The ecoflow series fulfills the internationally valid quality standard of the American Petroleum Institute API 675. It includes all definitions for a diaphragm metering pump in industrial use in terms of its design, construction, performance and acceptance test.

Safety and reliability in extreme operating states

For us, safety and reliability comes first: The pump is not subjected to damage, even after operating errors occur or in extreme operating states. We offer maximum protection for user and machine through built-in safety mechanisms - not only when excess primary pressure is present, but also when the pressure or suction line is closed.

Suitable for virtually all fluids

The ecoflow series is suitable for almost all liquids thanks to its flexible design. Whether they are dangerous, toxic, abrasive, viscous, environmentally harmful or sensitive fluids, the user-specific configuration always gives you the correct diaphragm metering pump.

Patented sandwich diaphragm

Our patented LEWA sandwich diaphragm is not only extremely durable, but also well-protected. The LEWA DPS diaphragm protection system and a diaphragm monitoring system allow us to ensure that the diaphragm does not tear during operation and that the pump fluid is not contaminated.

Integrated pressure relief valve

A pressure relief valve in the hydraulic part of the diaphragm pump prevents potential overload situations in operation. This valve is individually adjustable and can therefore be adapted to different operating situations.

High energy efficiency

LEWA diaphragm pumps achieve the highest efficiency of all pump technologies. Our ecoflow series also combines high efficiency with low energy consumption.

Hermetically sealed

Diaphragm pumps work without dynamic seals in the process fluid area. This forms a hermetically sealed working area. No emissions escape to the outside, and contamination of the fluid is impossible.